اختيار نوع الرف الثقيل

اختيار نوع الرف الثقيل

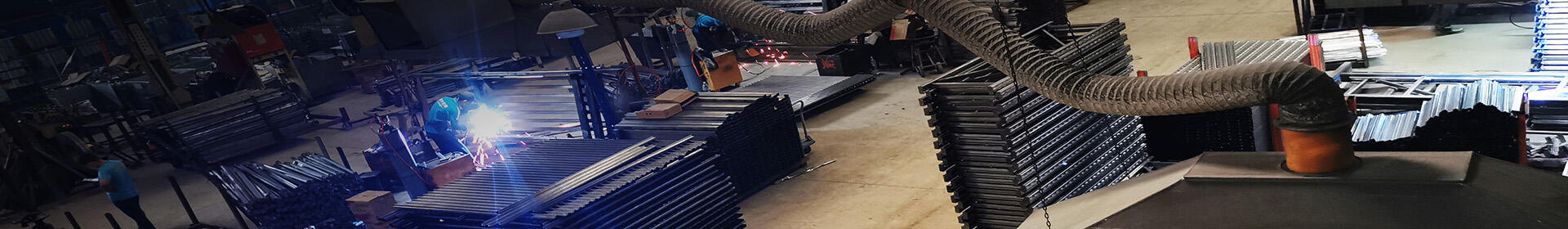

الرفوف الثقيلة عادة ما تكون رفوف اختيارية للباليت مع/بدون طبقات فولاذية أو شبكية.

هي مناسبة لتحميل أربع طبقات ويمكن تكوينها بمرنة في المستودع لسهولة الحركة، تعديل الارتفاع وإعادة التنظيم الجزئي.

تتكون هيكلية الرفوف الثقيلة من أعمدة، وعوارض، ودعامات أفقية، ودعامات مائلة، ومسامير، مما يمنع بفعالية عدم الاستقرار الناتج عن تراخي البراغي.

تمتلك الرفوف الثقيلة خصائص البساطة، والموثوقية، والخفة، وقدرة تحمل كبيرة، وتكلفة منخفضة. يتم تجهيز الاتصال بين المقابس العمودية والعمود بمسطر أمان خاص لضمان عدم سقوط العارضة تحت التأثير الخارجي. اللوحة لديها قدرة تحمل قوية، ومقاومة للتآكل، وهي سهلة الاستبدال والصيانة.

مزايا رف الشحن الثقيل:

1. يتم تعبئة وتغليف البضائع وتخزينها باستخدام托 palettes وأقفاص تخزين وغيرها من المعدات. عادةً ما يكون الحمل لكل وحدة حوالي 500-3000 كجم لكل Palette، ويتم وضع وحدتين في كل طابق.

2. تناسب معظم المستودعات أو المنتجات ويمكن تشغيلها بسهولة باستخدام شاحنات الحوافر وغيرها من آلات المناولة.

3. يتم تجهيز الأعمدة العمودية بمسافات فتحات قابلة للتعديل، والتي يمكن ضبطها وفقًا لارتفاع الشحنة.

4. يجب أن تكون مسافة العرض للرُفوف الوحدة ضمن 4 أمتار، وعمقها ضمن 1.5 متر. هناك قيود على ارتفاع رُفوف المستودعات المنخفضة والعالية وارتفاع رُفوف المستودعات الفائقة الارتفاع.

5. يتم استخدام معدات المناولة الميكانيكية للتخزين.

تحمل الرُفوف الثقيلة الأحمال

لدى الرُفوف الثقيلة قدرة كبيرة على تحمل الأحمال وتؤثر بشكل كامل في تخزين واسترجاع البضائع. عادةً تكون قدرة التحمل عند هذه الرُفوف وما فوقها، لكن قدرة تحمل الرُفوف المخصصة تكون عادة حوالي 1 إلى 2 طن.

تُستخدم على نطاق واسع في الصناعة والخدمات اللوجستية الثالثة ومراكز التوزيع.

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

TH

TH

MS

MS

HMN

HMN

KM

KM

LO

LO

MR

MR

TA

TA

MY

MY

SD

SD