MaoBang storage equipment - Factory section

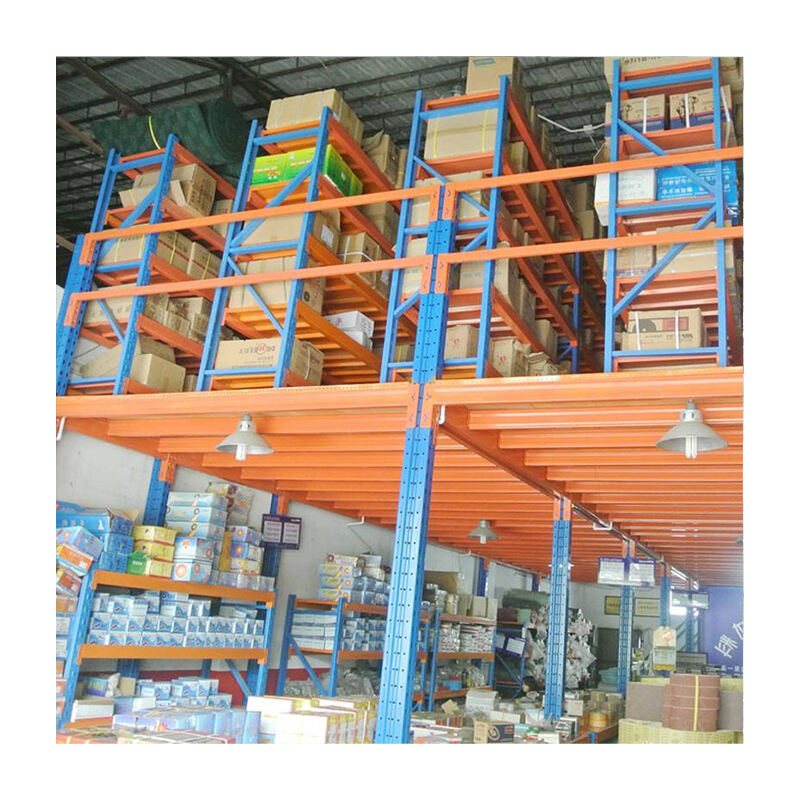

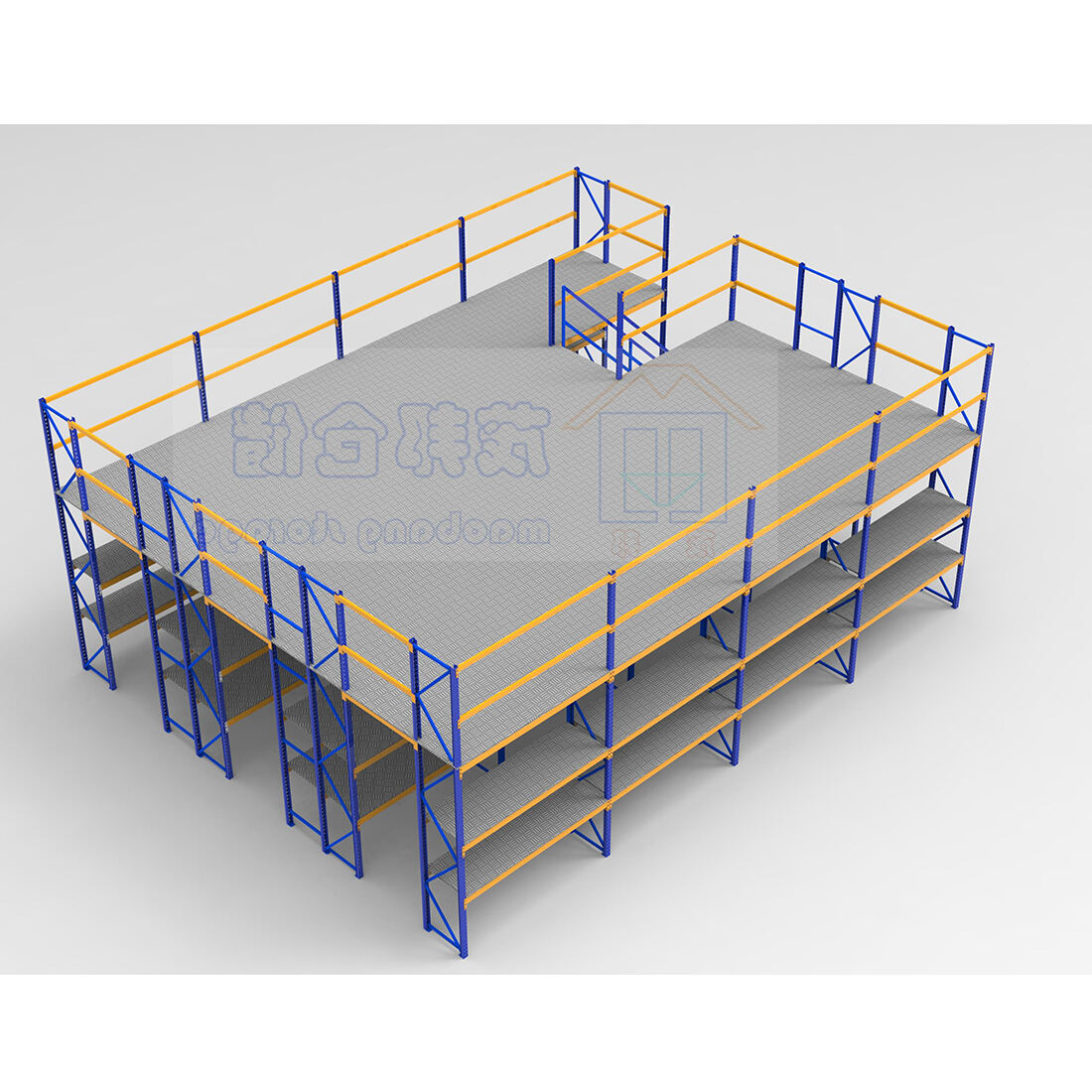

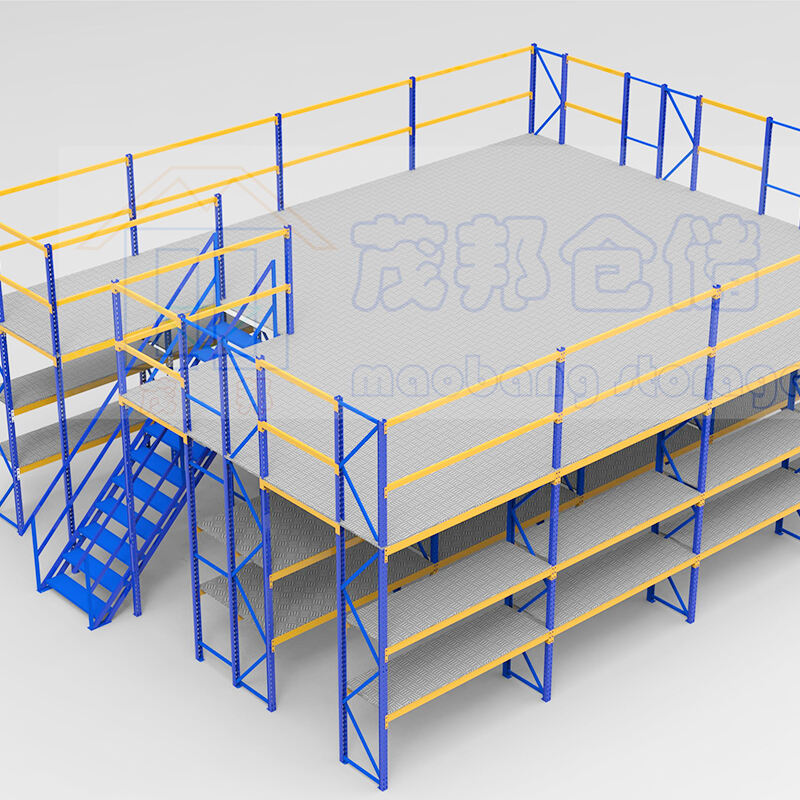

Shelves play a very important role in modern logistics activities. The modernization of warehouse management is directly related to the types and functions of shelves. Choosing the right storage shelves will not only bring unexpected benefits to the enterprise, but also save investment costs and operating costs.

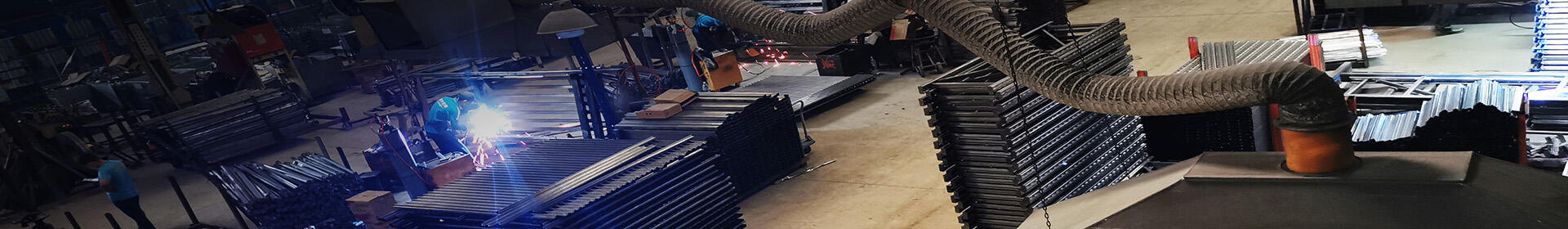

Today I will take you to the South China production base of Maobang Shelf and tell you how the shelves are made.

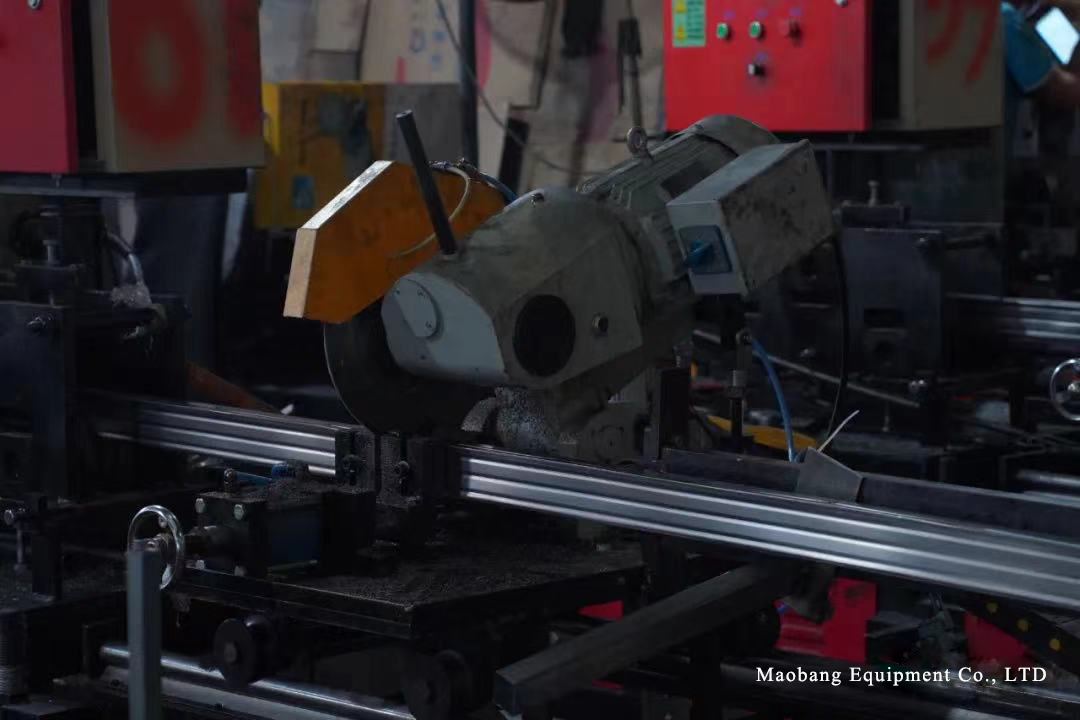

First, the strip steel will be cold-rolled through a rolling mill to form accessories such as columns, beams, and support beams for shelves.

The CNC punching machine accurately punches out the hole position on the column, and the whole process is automatically controlled by computer to ensure the accuracy of the hole position of each column.

In terms of physical properties, cold rolled steel is generally harder and stronger than standard hot rolled steel. The hardness, tensile fracture resistance, and deformation resistance of steel are due to low temperature forming, and work hardening increases its strength.

The overall structure of Maobang shelves is generally disassembled, but many places still use welding to increase the overall strength of the shelves, such as between the beam and the pendant, between the column and the foot, all need to be welded. The welding of shelves is different from other welding, which requires relatively high strength and must be operated in strict accordance with the specifications. In addition to meeting the general welding requirements, the welding of the shelves should also meet the requirements of the "Code for Seismic Design of Buildings" (GB-2001).

Maobang shelves are produced in strict accordance with the above standards, and the welding of some parts of the shelves adopts full penetration groove welding. The unique connection between the column and the beam, through this connection, the hinged form of the column and the beam can be changed to a rigid connection direction as much as possible; all the connecting bolts are friction-type high-strength bolts.

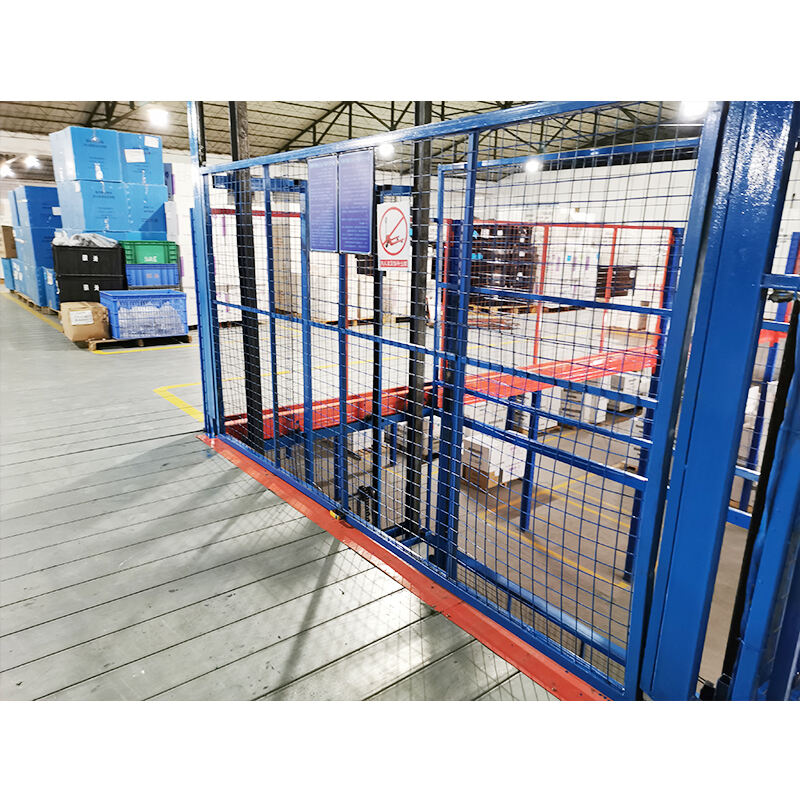

In order to ensure quality, efficiency and accuracy, Maobang Shelf Production Base has introduced a fully automatic laminate folding production line, which can automatically cut materials and fold four sides automatically. On the premise of ensuring quality, production efficiency and production accuracy are improved.

After all shelf accessories are formed, they will enter the spraying production line. The surface treatment of Maobang shelves adopts epoxy resin powder electrostatic spraying process, and the coating thickness is 60~80 microns; the electrostatic powder adhesion meets the requirements of grade 0 in the GB92865-88 standard; the hardness (wear resistance) is 100 of ordinary nitro paint 2H requirements in GB6739-86 standard, that is, no scratches after 2H pencil test.

Maobang shelf production base produces in strict accordance with various standards in the production process, and checks at every level, everything is for the shelf to be safer and more durable. Real materials, real goods "rack" real!

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

TH

TH

MS

MS

HMN

HMN

KM

KM

LO

LO

MR

MR

TA

TA

MY

MY

SD

SD