Storage shelves offer several advantages over directly stacking items. What are some of these advantages?

Utilizing shelves maximizes space efficiency and is a common practice across various industries. In the absence of shelves, items are typically stacked directly. What are the specific advantages of using storage shelves compared to traditional stacking methods?

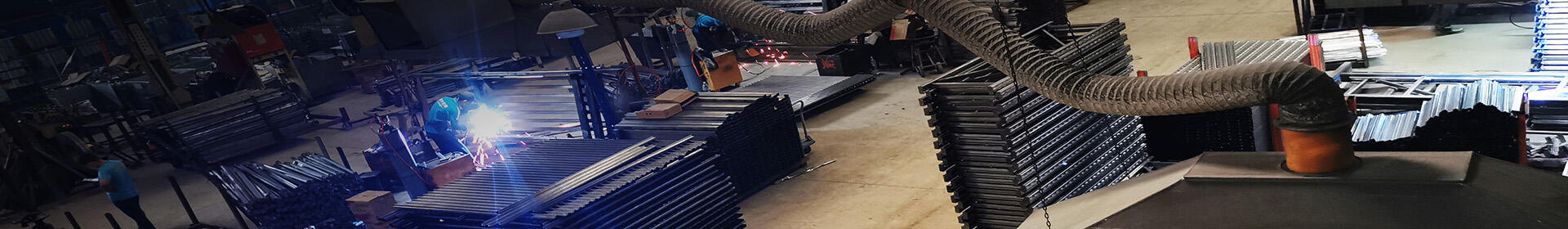

In modern management, optimizing storage space to save costs and enhance work efficiency has become a top priority for managers. Effectively utilizing warehouse space and maximizing its storage capacity are crucial considerations. There are two key aspects to focus on in storage management: increasing the effective use of storage space and facilitating the smooth flow of goods.

The area designated for storing goods is known as storage space. While it serves as a storage area on the surface, it also functions as a pivotal point for the acquisition, conveyance, and dissemination of goods. Consequently, the storage space has evolved into a critical hub for the storage and transport of goods. As a result, optimizing the use of storage space has become an important focus for managers and operators of logistics centers. This has placed greater demands on shelving systems. The rise of modern warehouses has propelled the evolution of shelving technologies.

Utilizing heavy-duty shelves in warehouses optimizes storage space, enhances storage capacity utilization, and amplifies overall storage capacity. This method ensures that stored goods are not compressed, minimizes material loss, and provides full protection for the materials, ultimately minimizing loss of goods.

The shelves are designed for easy storage and access, streamlined inventory management, and efficient utilization of space. Various measures, such as moisture-proofing, dust-proofing, and anti-theft mechanisms, can be implemented to maintain the quality of stored goods. Additionally, modern shelf designs support the mechanization and automation of warehouse management, contributing to improved efficiency.

In traditional methods, stacking goods into piles can make it difficult to manage inventory effectively. It requires extracting items from the bottom layer and rearranging those on the upper layer before accessing the desired goods. This process consumes time, space, and labor.

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

TH

TH

MS

MS

HMN

HMN

KM

KM

LO

LO

MR

MR

TA

TA

MY

MY

SD

SD