What are the different options for heavy-duty shelves?

There are various types of heavy-duty shelves available, including ordinary heavy-duty shelves, also known as low-heavy shelves and beam shelves. These shelves are typically designed to hold four layers of loads. They can be arranged in different configurations within a warehouse, allowing for easier movement, adjustment of shelf height, and partial reorganization.

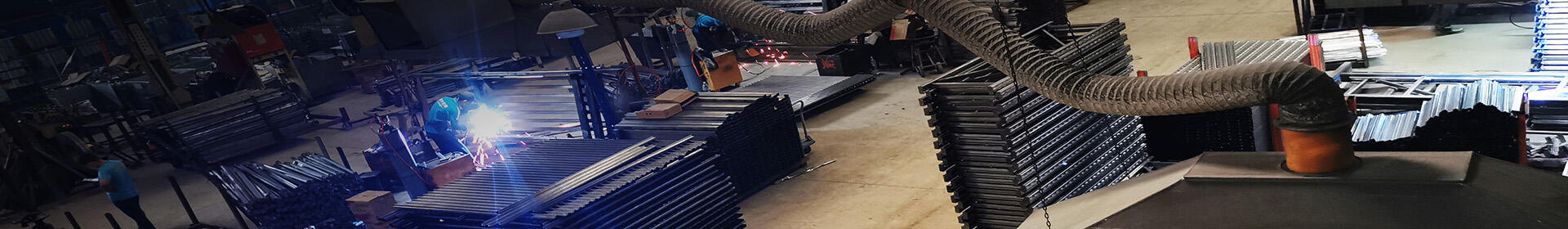

The heavy-duty storage shelves feature sturdy construction with columns, beams, cross braces, diagonal braces, and self-locking bolts, providing stability and preventing the shelves from becoming unstable. Specially designed closed beams and safety pins ensure the reliability and safety of the structure, while internationally made strip layer boards offer strong bearing capacity, wear resistance, and easy maintenance.

Key features of heavy-duty shelves:

1. Goods are typically stored on these shelves after being packed using unit container equipment such as pallets and storage cages. The load per unit is generally within a specific range, with two units usually placed on each layer.

2. Heavy-duty shelves are widely used and are suitable for most warehouses or product goods.

3. They enable easy picking of goods, and handling machinery like forklifts can access any cargo position for convenient and fast storage operations.

4. The height of each layer is adjustable in integer multiples.

5. The unit shelf typically spans within 4m, with a depth of 1.5m. The height of low and high warehouse shelves is generally within a specific range, and ultra-high warehouse shelves fall within another specific range.

6. Mechanical handling equipment is utilized for storage operations.

What is the typical weight capacity for heavy-duty shelves?

Heavy-duty shelves are known for their impressive load-bearing capacities and their ability to efficiently store and retrieve a wide range of items. Many companies, including third-party logistics providers, rely on heavy-duty shelves due to their robust load-bearing capabilities. Typically, the load-bearing capacity of heavy-duty shelves exceeds 1-2 tons, making them suitable for various applications in manufacturing, third-party logistics, and distribution centers. Additionally, these shelves are equipped with adjustable hole spacing, allowing for customized adjustments based on the height of the stored goods.

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

TH

TH

MS

MS

HMN

HMN

KM

KM

LO

LO

MR

MR

TA

TA

MY

MY

SD

SD